Part & Mold Design for Injection Molding

Course Description

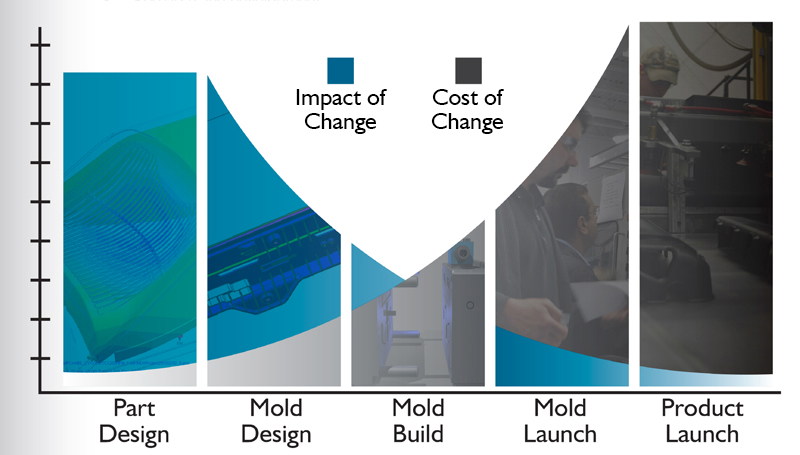

To successfully design and produce plastic injection molds and molded components that meet cycle time, cost, part quality, and lead time requirements, networks of molding professionals need to have a common language and an understanding of core elements of plastic behavior. This course will help you understand the inter-relationships of part design, mold design, and quality processing, allowing you to better:

- Maximize the likelihood of successful production

- Mitigate rework

- Reduce development costs

- Decrease the risk of less-than-optimum tooling conditions

- Minimize nonconformities

- Speed up time to market

Course Objectives

- Outline good manufacturing processes (GMP) for plastic part design, molding non-conformities, and tolerances

- Explore fundamental material characteristics

- Evaluate robust mold designs

- Examine necessary processing characteristics

- Recognize how part design and material selection affect the cost of tooling and piece price

- Identify non-conformities and how to resolve them

Course Recommendations

It is strongly recommended that the participant has successfully completed the following courses, or has equivalent knowledge/experience:

- Essentials of Injection Molding

- Math for Molders

- OR a minimum score on the online training placement questionnaire

Delivery Format Options

This course is available publicly and in-plant.

Daily Schedule Overview

(Subject to change at instructor discretion.)

| Day 1 | Day 2 | Day 3 | Day 4 |

| Plastic material classifications | Part design features | Injection molding machine capabilities and limitations | Mold venting |

| Plastic material properties | Part print specifications | Injection mold classifications and types | How the mold steel selection impacts part surface specifications and cooling efficiency |

| How the product environment and part critical functions affect the material selection | Plastic part decoration and assembly techniques | Mold movement, alignment components, and mold actions | Mold cooling system |

| Part design considerations and best practices | Mold filling simulation utilized to identify many items such as: gating location & type, filling pattern, cooling efficiency, and possible visual non-conformities | Melt delivery systems and gating types | Molding process strategies, part removal, mold care, and next steps |

| Start Date | End Date | Nome | Linguaggio | Posizione | Open Seats | Prezzo | |

|---|---|---|---|---|---|---|---|

| 2026/11/10 | 2026/11/13 | Part & Mold Design for Injection Molding | Spanish | Guadalajara, Jalisco | 5+ | $1,945.00 | Register |

| 2026/05/19 | 2026/05/22 | Part & Mold Design for Injection Molding | English | Opelika, Alabama | 5+ | $1,945.00 | Register |