Tip of the Day 131: Naming Temperature Sensors

I recently discovered that a customer had made an error in naming the locations of in-cavity temperature sensors. The rules are these:

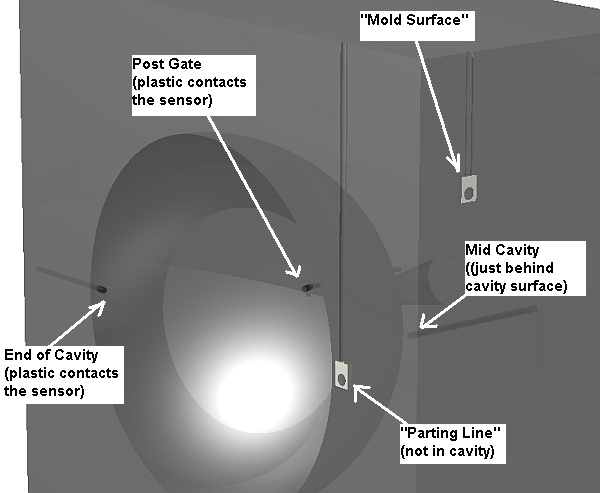

If the plastic contacts the sensor or the sensor is just behind the cavity wall use one of the in-cavity locations:

Post Gate, Mid Cavity or End of Cavity. Then add an id for each cavity in multi-cavity applications.

For in-cavity sensors pick a location name relative to the flow path.

If the sensors are on the mold steel elsewhere you can use Parting Line or Mold Surface.

This diagram shows examples of sensor placement and naming that depict the above rules. Note that there is no rule that the mid-cavity be behind. This is just an example.

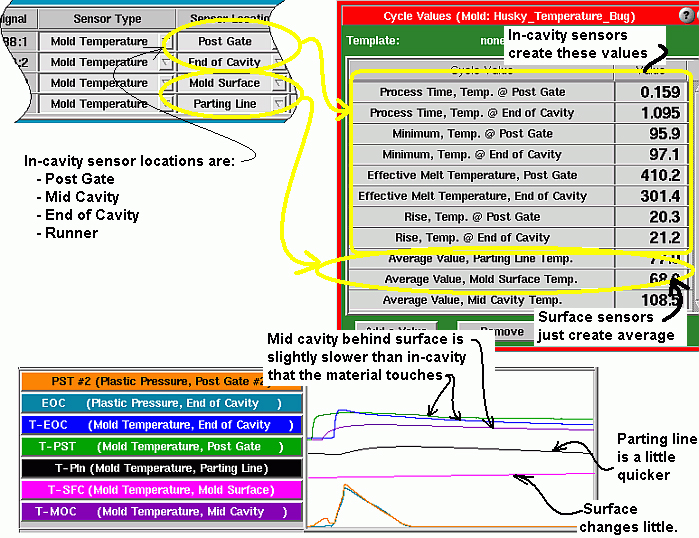

The summary values calculated and the data storage rate both depend on the location names you choose. In-cavity sensors are stored at full speed and calculate a variety of values. The others (such as Mold Surface and Parting Line) are expected to be slower, store fewer data points and calculate fewer values.