We talk a lot about injection molding process optimization, but what does that entail? What parameters need to be perfected in order to reach maximum optimization? Here are the 8 key parameters in injection molding that you need to align in order to produce consistent, high quality plastic parts.

1. Temperature Control:

Plastic or Melt Temperature: Proper control of the plastic temperature is essential for melting the plastic uniformly. Different materials have specific temperature requirements, and maintaining the correct temperature range prevents issues like incomplete melting or thermal degradation.

Mold Temperature: Controlling the mold temperature affects the part’s crystallinity, shrinkage, and cycle time. Keeping the mold at the recommended temperature helps to ensure that the resin has the correct mechanical characteristics.

2. Injection Speed:

The rate at which molten plastic is injected into the mold affects the filling pattern, part density, and overall quality. Fill speed also has an effect on the packing phase of the molding process. Adjusting the injection speed helps prevent issues like flow lines or air traps.

3. Cooling Time:

The cooling time is the duration the part spends in the mold after the material has been filled and packed. Proper cooling time is crucial for preventing warpage and ensuring the part solidifies uniformly. It also influences the overall cycle time of the injection molding process.

4. Plastic Material Selection:

The choice of plastic material has a significant impact on the injection molding process. Different materials have varying melting points, shrinkage rates, and flow characteristics. Selecting the appropriate material for the intended application is essential for achieving the desired part properties.

5. Screw Speed and Back Pressure:

Screw Speed: The rotational speed of the screw in the injection molding machine affects the material’s overall shear. Screw speed should be selected based on the type of material and the additive content. The correct screw speed will ensure that the correct amount of shear is provided by the rotation of the screw and the screw geometry.

Back Pressure: Maintaining the right back pressure on the screw ensures proper mixing and homogenization of the molten plastic. It also helps in preventing voids and improving part quality.

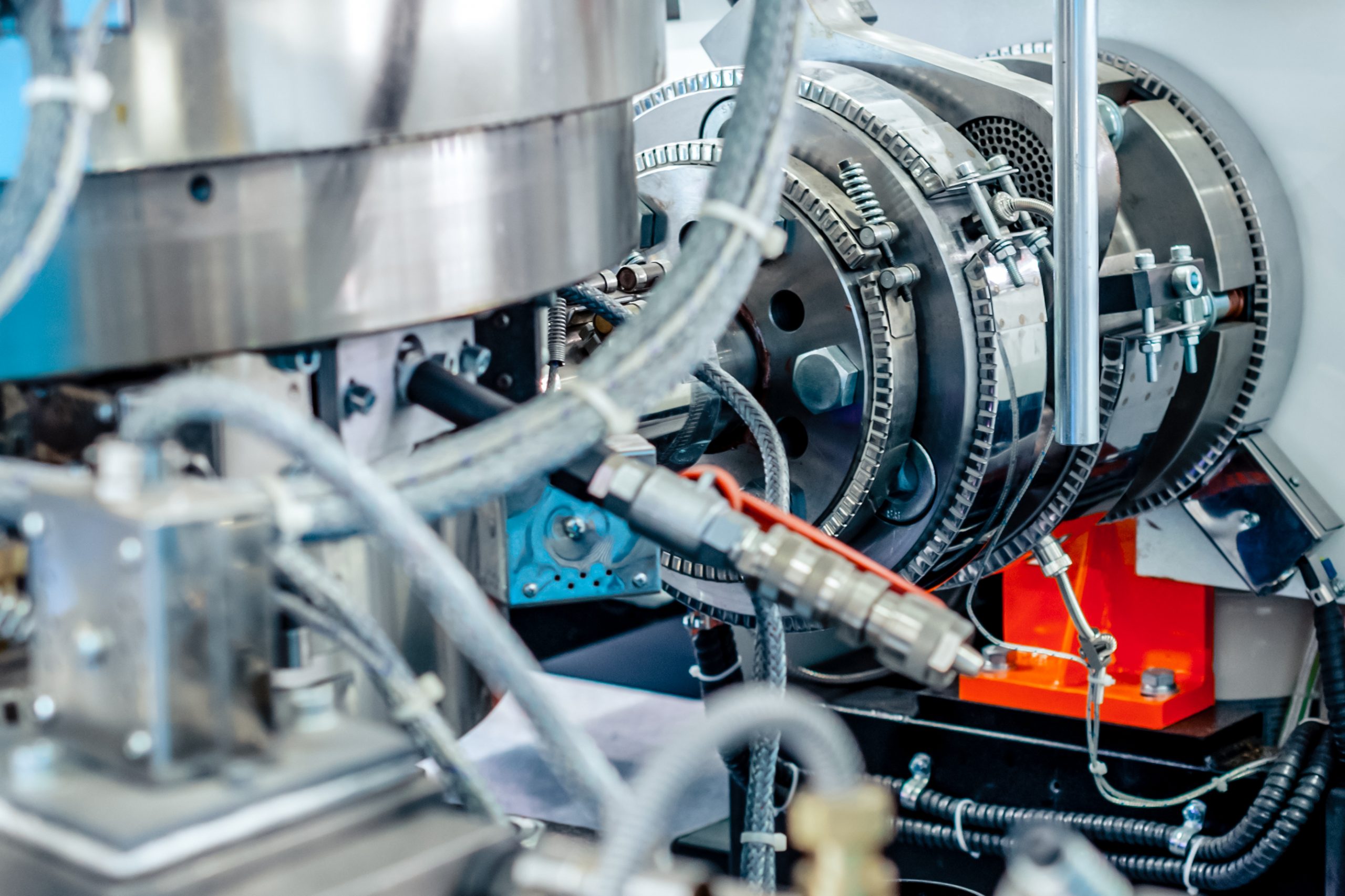

6. Injection Molding Machine Calibration:

Regular calibration of the injection molding machine is crucial for maintaining accuracy in the process. This includes calibration of the machine’s pressure, temperature, and timing settings.

7. Mold Design and Maintenance:

Well-designed molds with proper venting, gating, and cooling channels contribute significantly to the optimization process. Regular maintenance of molds is essential to prevent issues like wear, corrosion, or damage that can affect part quality.

8. Monitoring and Control Systems:

Implementing advanced monitoring and control systems (such as CoPilot®) allows real-time tracking of various parameters. This enables quick identification of deviations and facilitates prompt corrective actions, contributing to continuous improvement in the injection molding process.

Conclusion

Optimizing the injection molding process is a multifaceted task that involves meticulous attention to various parameters. By fine-tuning temperature, pressure, speed, and other key factors, you can achieve consistent, high-quality results while minimizing defects and cycle times. As technology advances, the integration of smart systems and real-time monitoring further enhances the efficiency and reliability of injection molding processes. Continuous efforts in process optimization contribute to the overall success and competitiveness of plastic manufacturing industries.