In today’s fast-paced business environment, efficiency is a key factor in the success and profitability of any organization, including injection molding businesses. Enhancing operational efficiency not only improves productivity but also reduces costs, maximizes output, and ensures customer satisfaction. This article outlines practical strategies to make your injection molding business more efficient and position it for sustainable growth.

1. Streamline Processes and Workflow

The first step toward efficiency is to analyze and streamline your processes and workflow. Identify bottlenecks, redundancies, and areas of waste in your operations. Utilize lean manufacturing principles to eliminate non-value-added activities, optimize material flow, and reduce cycle times. Ensure smooth coordination between different stages of production, from design and tooling to molding and finishing, to minimize downtime and maximize throughput.

2. Optimize Machine Utilization

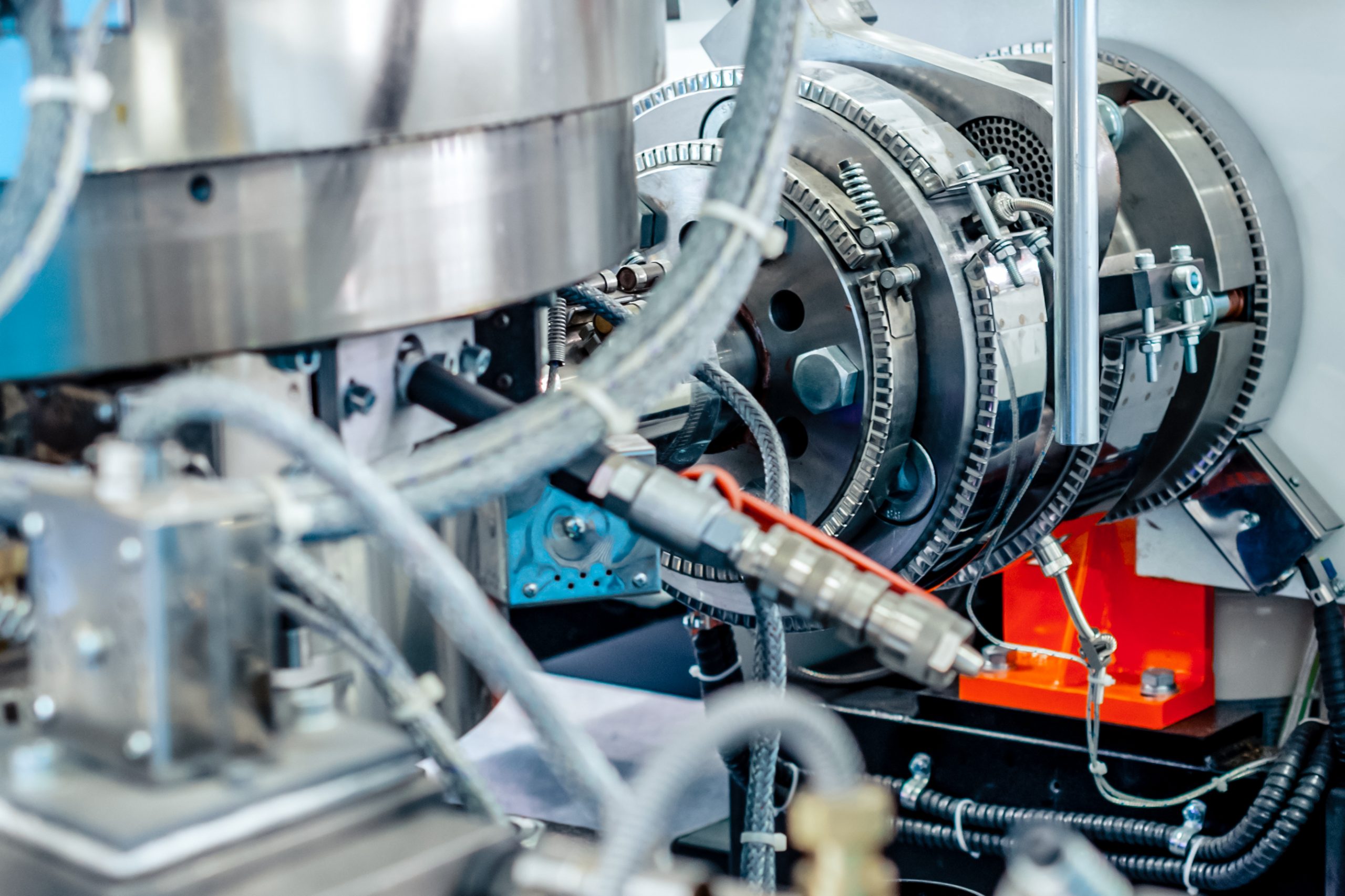

Efficient utilization of machinery is crucial for productivity and profitability. Analyze machine utilization rates and identify opportunities to improve efficiency. Consider factors such as scheduling, production planning, and maintenance practices. Optimize production schedules to maximize machine uptime and minimize changeovers. Implement preventive maintenance programs to minimize breakdowns and reduce unplanned downtime. Regularly assess the need for equipment upgrades or replacements to ensure optimal performance.

3. Invest in Advanced Technology

Leveraging advanced technology can significantly enhance efficiency in injection molding operations. Automation, robotics, and computer-aided design/manufacturing (CAD/CAM) systems can streamline processes, improve accuracy, and reduce manual intervention. Automated material handling systems can optimize material flow, minimize waste, and increase productivity. Utilize real-time monitoring and control systems such as the CoPilot® to track machine performance, quality metrics, and process variables for timely adjustments and continuous improvement.

4. Implement Effective Production Planning

Efficient production planning is crucial for meeting customer demands and optimizing resources. Utilize production planning tools and software to forecast demand, schedule production orders, and allocate resources effectively. Implement just-in-time (JIT) principles to minimize inventory and reduce carrying costs. Consider demand patterns, lead times, and customer preferences when determining production quantities and scheduling. Align production planning with your supply chain to ensure timely availability of materials and components.

5. Enhance Material Management

Effective material management plays a vital role in injection molding efficiency. Optimize material procurement by maintaining strong relationships with reliable suppliers and negotiating favorable terms. Implement efficient material handling and storage practices to minimize waste, prevent contamination, and ensure easy access during production. Utilize real-time tracking systems to monitor material inventory levels and enable timely reordering. Adopt material traceability systems to ensure quality control and compliance.

6. Continuous Employee Training and Engagement

Invest in the professional development and engagement of your workforce. Provide comprehensive training programs to enhance technical skills, safety awareness, and problem-solving abilities. Cross-train employees to handle multiple roles, allowing for flexibility and smoother workflow. Encourage employee engagement and empower them to contribute ideas for process improvement. Foster a culture of continuous learning, open communication, and collaboration to drive efficiency throughout the organization.

7. Implement Effective Quality Control

Maintaining high-quality standards is paramount in the injection molding industry. Implement a robust quality control system to prevent defects and minimize rework. Conduct regular inspections and testing to identify and address issues early in the production process. Utilize statistical process control techniques to monitor key quality metrics and ensure consistency. Utilize The Hub® to continuously analyze quality data, identify root causes of defects, and implement corrective actions to drive continuous improvement.

8. Embrace Data-Driven Decision Making

Utilize data analytics to make informed decisions and drive efficiency improvements. Collect and analyze data on production metrics, machine performance, quality indicators, and cost drivers. Leverage data visualization tools and dashboards to gain insights into operational bottlenecks, identify improvement opportunities, and monitor key performance indicators. Use data-driven insights to optimize processes, allocate resources efficiently, and make strategic decisions that positively impact efficiency and profitability.

Conclusion

Improving efficiency in your injection molding business requires a comprehensive approach that encompasses streamlined processes, optimized machinery, advanced technology, effective planning, and continuous improvement. By investing in employee training, implementing effective quality control, and embracing data-driven decision making, you can drive efficiency at every level of your organization. Remember that efficiency is an ongoing journey, and regularly reassessing and refining your operations will help you stay ahead of the competition, reduce costs, and deliver exceptional value to your customers.

Next Steps

Sound a bit overwhelming? Let us help! Our new RJG SMART MethodSM will provide an in-depth analysis of the health of your organization, pinpoint areas of improvement, and create a custom plan to improve your profitability. Then we will help with implementation and ensuring your entire team is onboard.