Tip of the Day 100: Who is Controlling the Process?

For those running cavity pressure control using the eDART the question arises: Is the eDART controlling transfer or is the machine doing so? We have discussed adding various features to select a “master” control on the eDART and other ideas. Here is a simple one that you can use to discover whether the eDART is actually performing the control as required or not.

Typically what happens is that you have set up a very nice cavity pressure setpoint but someone has set a machine timer or position that does not allow the eDART to reach the setpoint. Or they have turned off external transfer on the machine. In any case the eDART tries to transfer the press but the press does not transfer at the right time. All you need to do to detect this is to set a warning or alarm around Value at V->P Xfer for the sensor you are using for control.

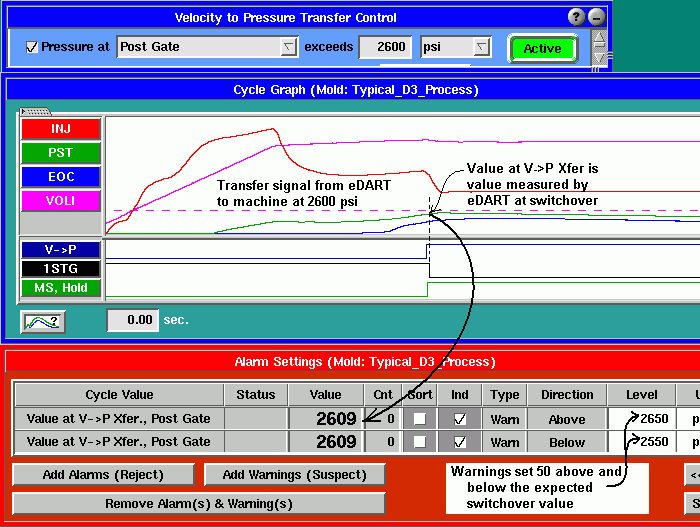

Warning Set, Process Transferring Correctly on Post Gate

In the following example the eDART IS doing the transfer. We have a cavity pressure transfer value set to 2600 psi on the Post Gate sensor. The warning window is set +/- 50 psi around the 2500 psi. The eDART uses the machine’s first stage signal to determine when the switchover occurs. The value it sees on the Post Gate sensor at the time first stage goes off is Value at V->P Xfer / Post Gate.

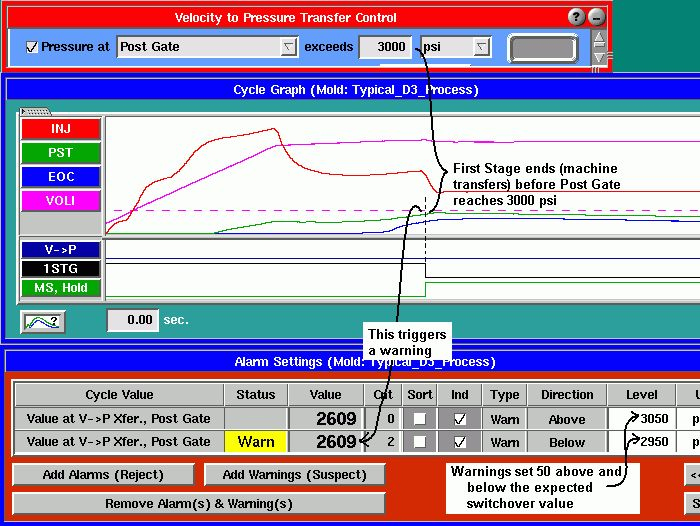

Warning Set, Process Not Transferring on Post Gate

Now consider the case below when the eDART was supposed to be transferring the press at 3000 psi. The value measured at transfer is closer to 2600. Again the warnings are set +/- 50 psi around the setpoint. In this case the eDART catches the fact that the transfer did not occur at the correct setpoint and sets a warning visible on the system overview, turns on an indicator light or sends a message through the Alert software.

Note that the “Sort” switches are turned off. In this example we have decided to alert someone using the System Overview, light tree or Alert but not to actually sort parts. We probably have cavity pressure integral or other alarms for actual part sorting using in-cavity measurements. If the transfer control is not operating from the eDART but the parts are still good (per the other alarms) then those parts do not need to be rejected. Yet the technician would be alerted to look at the problem and discover why the process is not using eDART control.

Note also that we have used a warning for this non-sorting purpose (“Add Warnings” with sort switch off). We suggest you create a policy of using warnings for things that require preemptive action but are not critical to the parts. If you are not doing 3-way sorting then the sorting switch should be off for those cases. When the supervisor sees a “Warning” on the system overview he knows that someone should look at the process to check the reason (under the count column) and adjust as necessary. When he sees “Alarm” he knows that the parts are being thrown away and immediate action is required.