Tip of the Day 37: Machine Fill from Inj. Peak

In Tip #36 you saw how the eDART uses a fixed fill volume number to mark the end of fill, as the machine says it.

Typically the user forgets to set the fill volume when he starts up a mold1 (see footnote at end). The sequencer starts with a default fill volume of 10000 cu. in. – a number that volume never reaches. So it uses the next best thing to denote the end of fill: peak injection pressure.

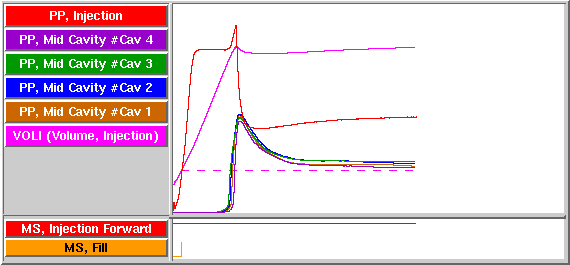

You can notice immediately that it is using peak injection pressure because it can’t figure out where fill ends until the end of the cycle. So the Machine Sequence / Fill trace (orange below) goes up at the start of fill and then just “sticks” there, drawing no horizontal line.

At the end of injection the sequencer looks back, finds the injection pressure peak and marks this as the end of fill. It draws the rest of fill and, if hold is shown, draws the start and end of Machine Sequence / Hold at that time as well. Also you can see that the sequencer has just two bars in the Fill tab’s “Off Quality” section (use the drop question mark for help there).

The Problem: What if Injection Pressure Peak is Not at End of Machine Fill Speed?

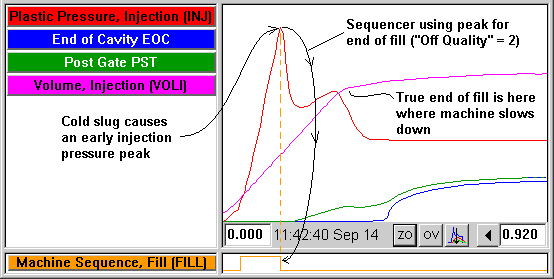

Many times there can be a cold slug in the nozzle or in hot runner tips that the injection unit needs to push out to get injection start. So the peak pressure may not be that at the end of fill. This will create a false end of fill and so not compute good viscosities, speeds and times. Here is an example.

What if the Peak Alternates

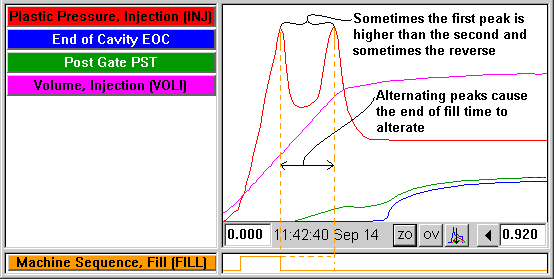

Sometimes the spike from the cold slug is very close to the actual peak when the machine slows down. In that case the end of fill may oscillate between the two times to peak as shown below. This causes the computations of viscosity and times to vary wildly and create useless data.

1The footnote at the end

Since it has been a perennial problem that people forget to set the fill volume I have developed a tool that does it for you: “Auto-Set Fill Volume”.

This is a bit of an experimental tool. It watches the stroke / volume sensor and uses the first dramatic slow-down (change in slope) to decide where the machine fill ends. It waits for 10 stable cycles in which it gets the same end of fill volume. Then, if the sequencer does not have a fill volume set yet it puts in the average from those 10 stable cycles as the fill volume. If the sequencer already has a fill volume the Auto-Set Fill Volume function will not overwrite it.

This has worked when tested against most of the customer data we have collected here and is running at one customer. It has some limitations as follows.

- If you never run stable shots very long it will never set volume (i.e. as our students often do in the lab).

- If you intend to run rheology curves and your machine goes to a different end position as you change speeds then you will need to set the fill volume manually before running the rheology curve.

- If there is noise on the stroke signal it would get the wrong fill volume.