Give your company the potential for zero defect molding

Your competitive advantage begins with complete process control

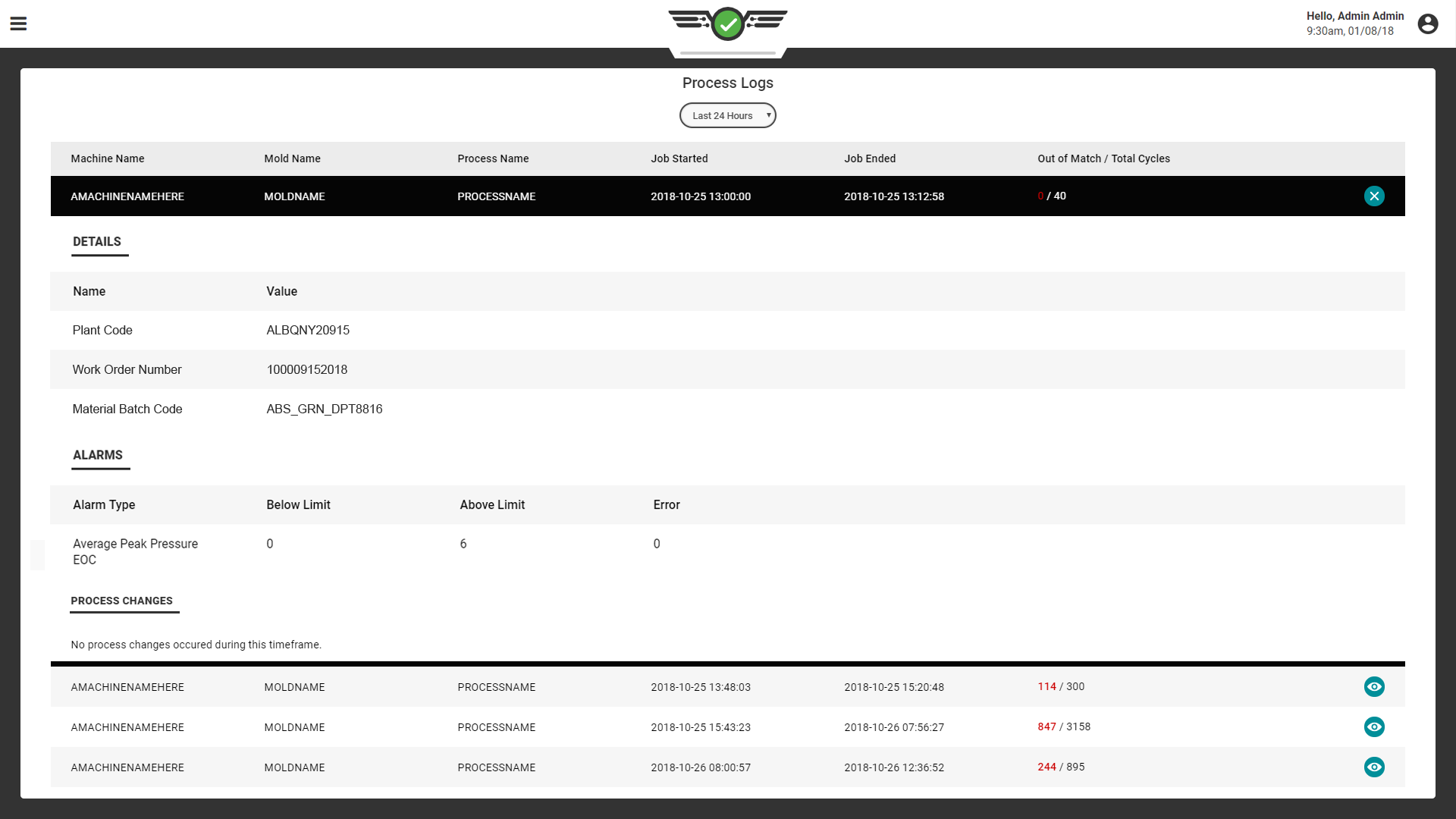

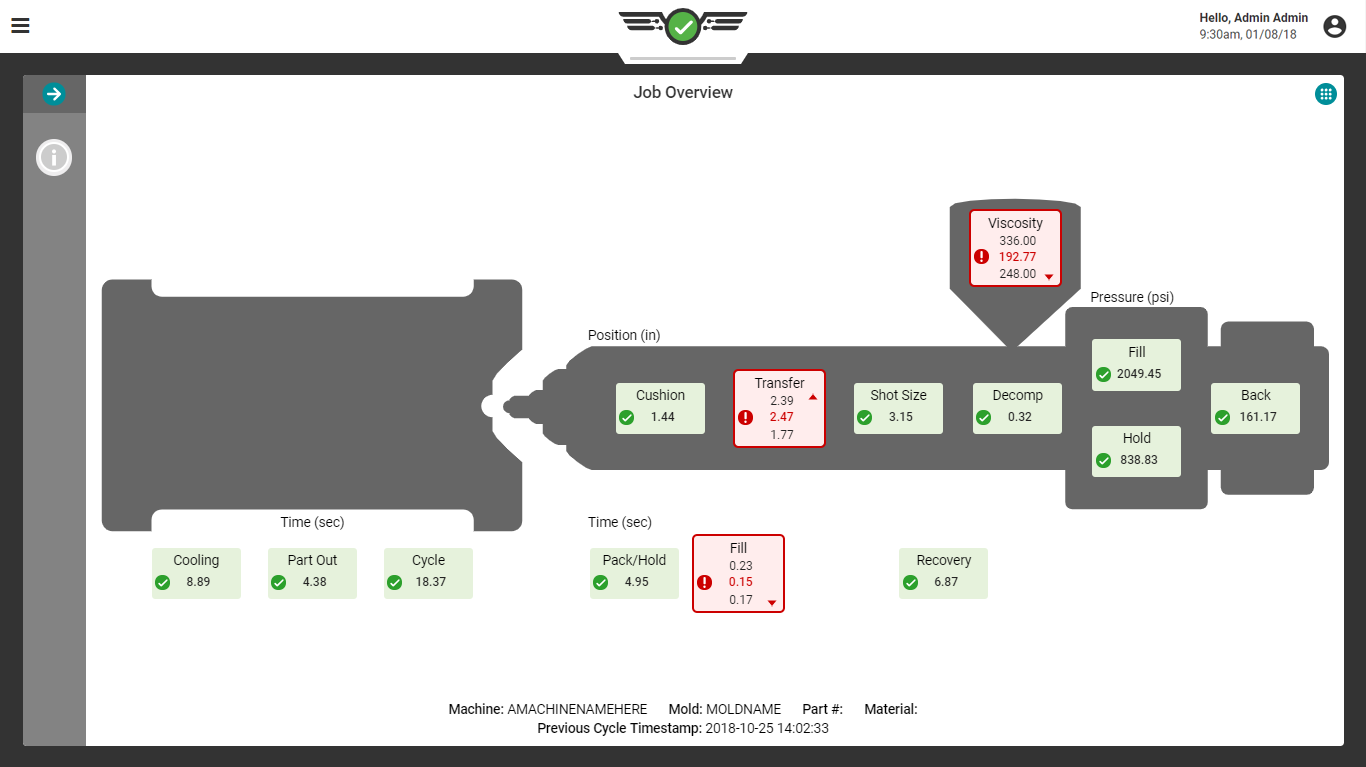

Know what’s happening in the mold

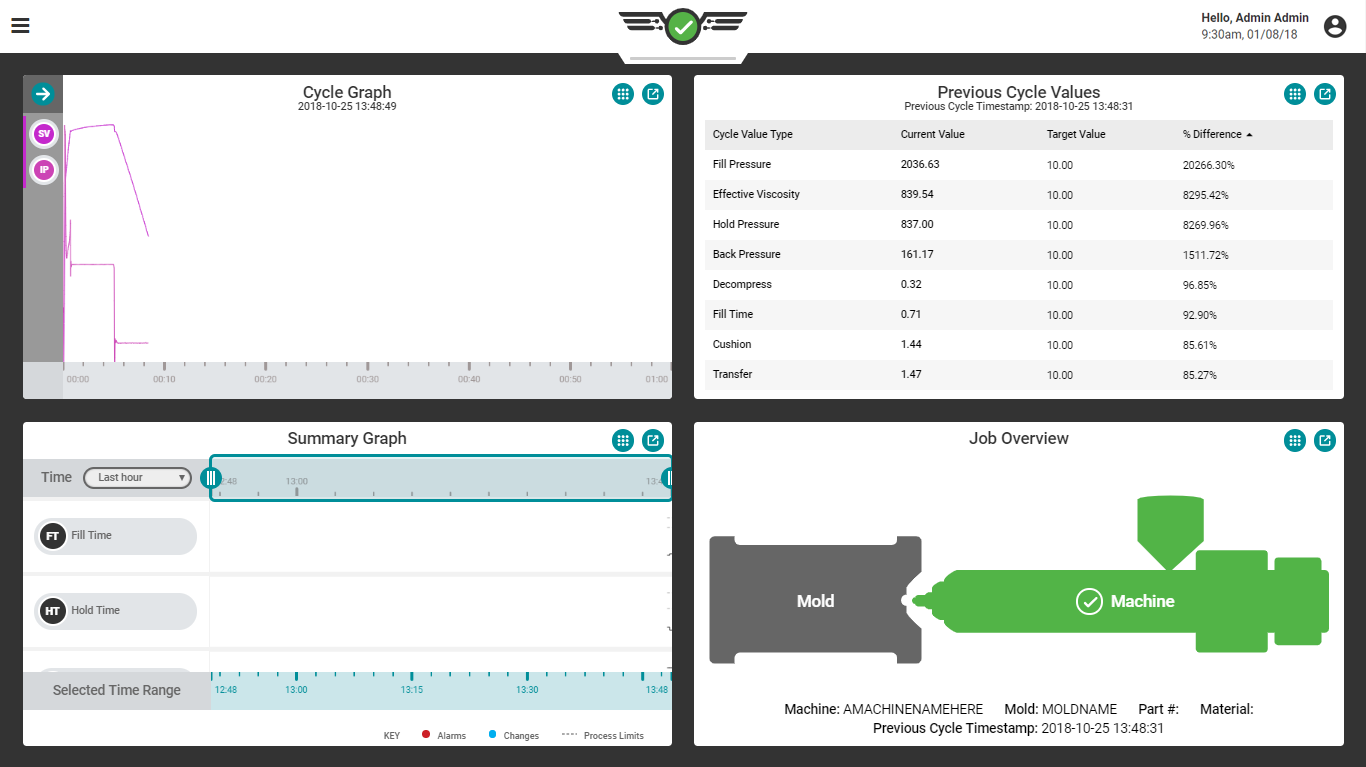

- View data from each shot

- Easily find where the problem is

- Speed up troubleshooting and down time

Improve quality

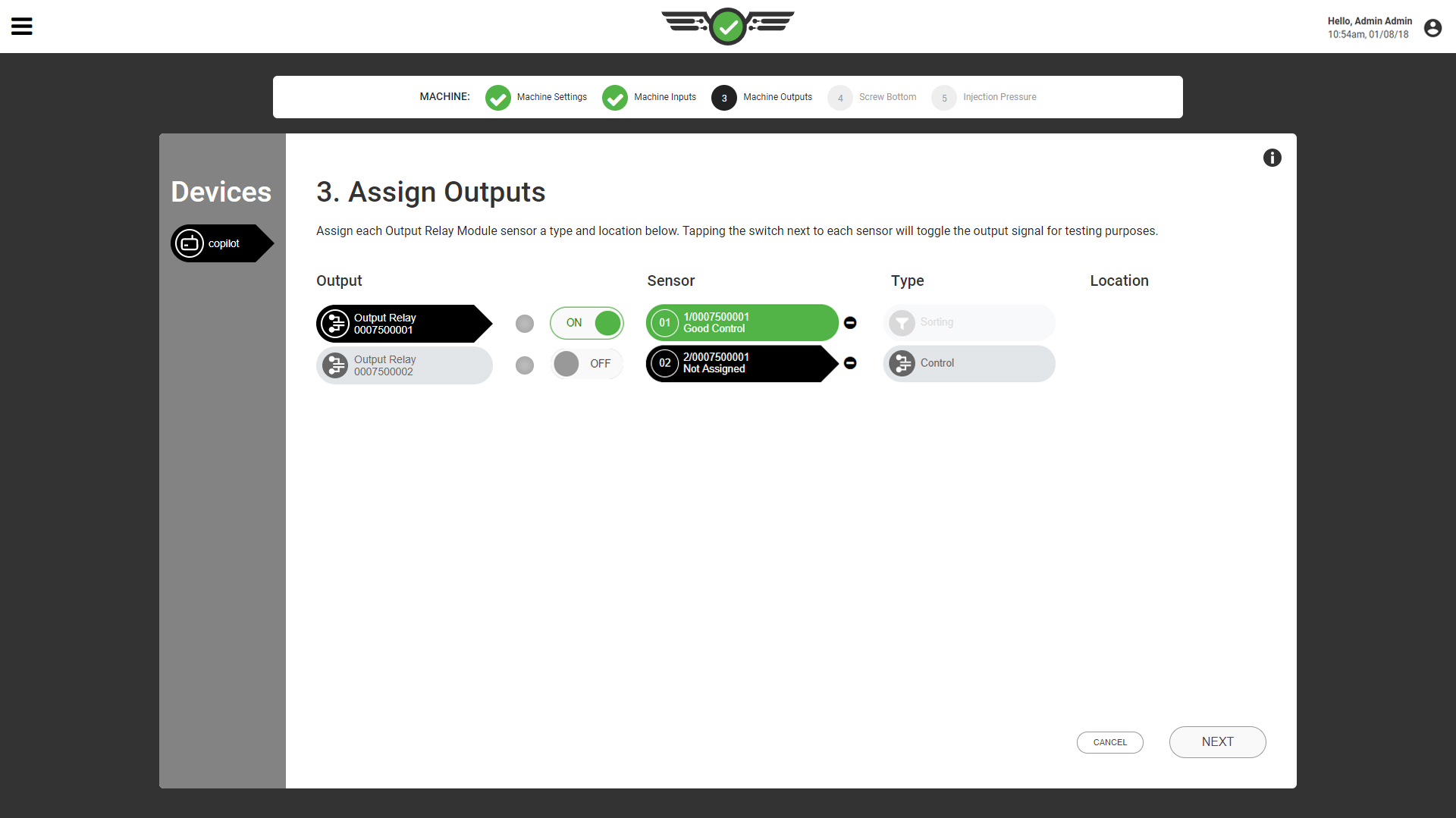

- Gain consistent part quality

- Build templates for process matching

- Reduce effects of material variation

Ensure efficiency

- Ensure consistency across the globe

- Reduce risk of human error

- Retain parts to reduce the risk of shipping bad parts

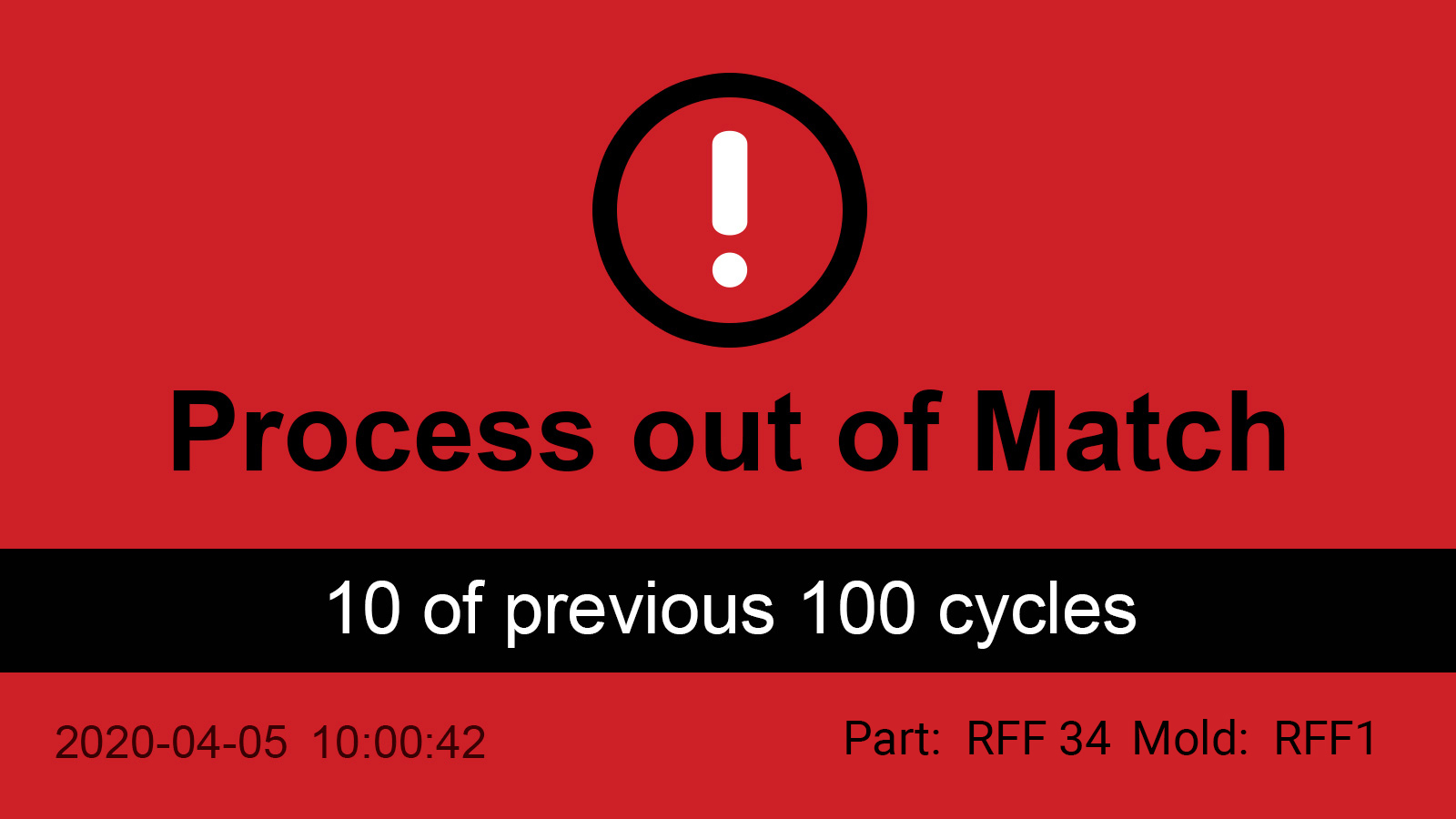

Real-time notifications

- Know the moment a process changes

- Reduce machine downtime

- Lower waste and make good parts again fast

Product documentation

Access useful information and guides for the CoPilot system. Don't see what you need? Let us know!

CoPilot resources