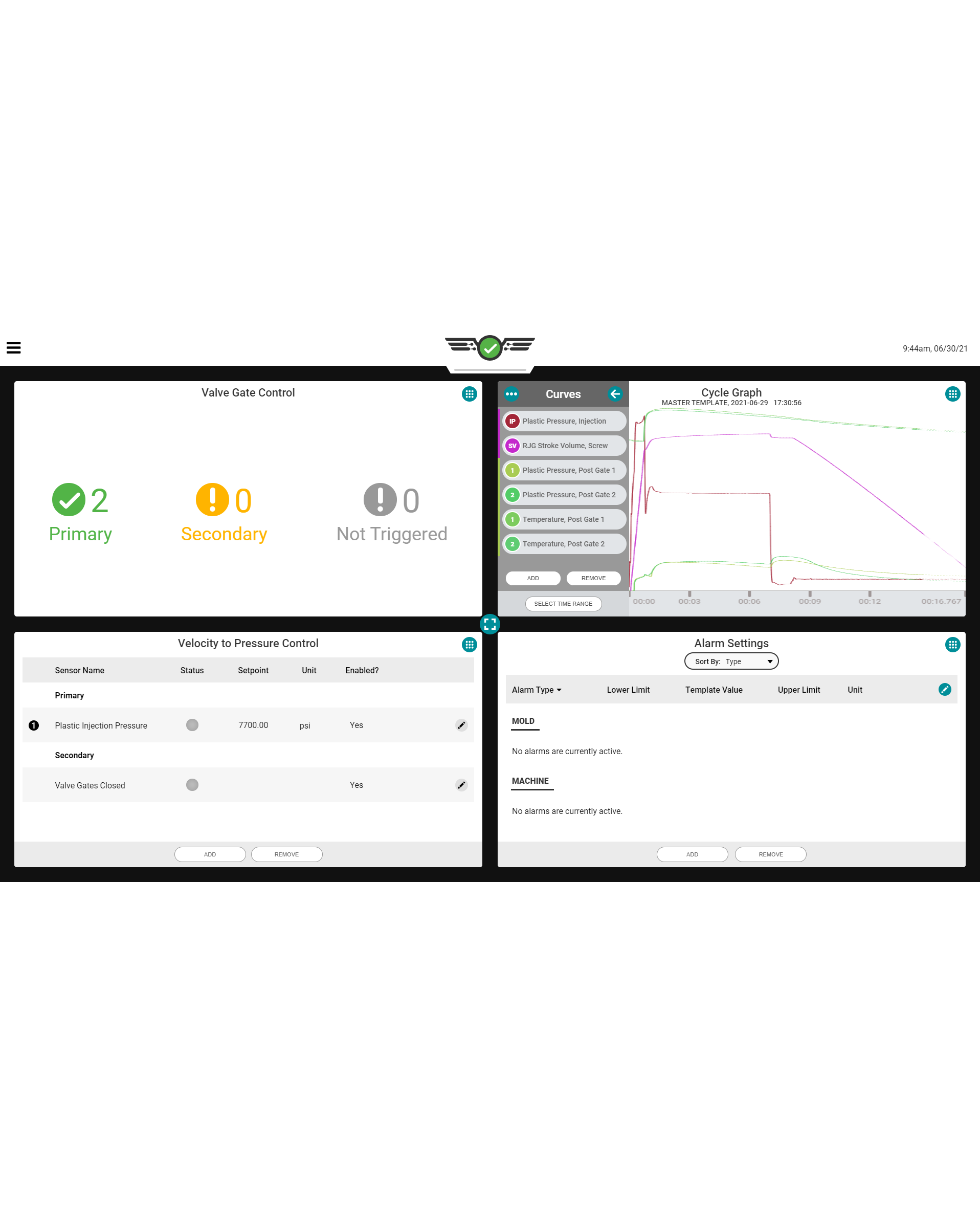

Improve efficiency to offset higher production costs

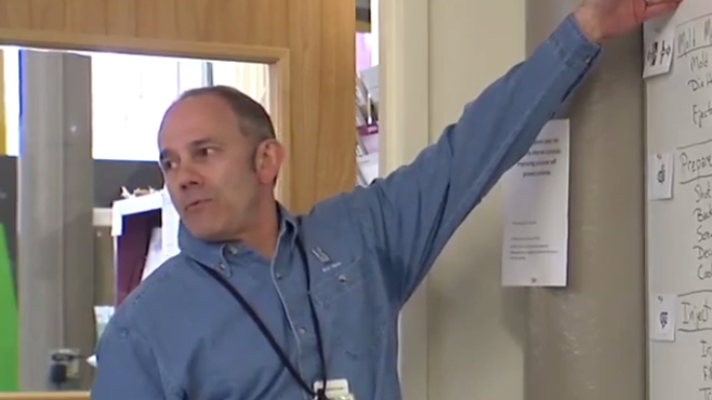

With higher resin costs and labor shortages across the industry, efficiency is more important than ever. Through our technology, you can easily trace every part shipped, prove good parts, and automatically sort suspect parts to ensure all shipped products are safe for medical use. Training will ensure your staff is running as efficiently and competently as possible while speaking the same language across departments.

How are we different from other injection molding solutions companies?

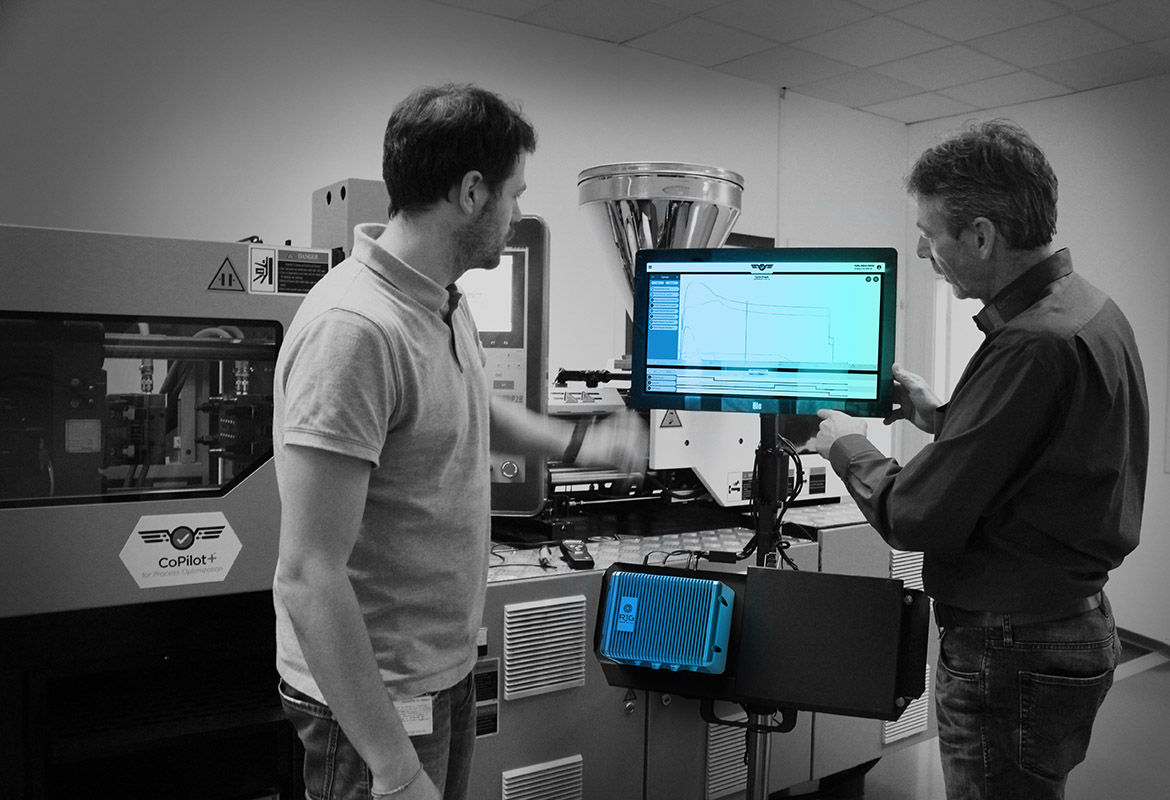

RJG medical molding resources