Technology evolves—so should your process control.

Stay Ahead with the Future of Process Control with The CoPilot

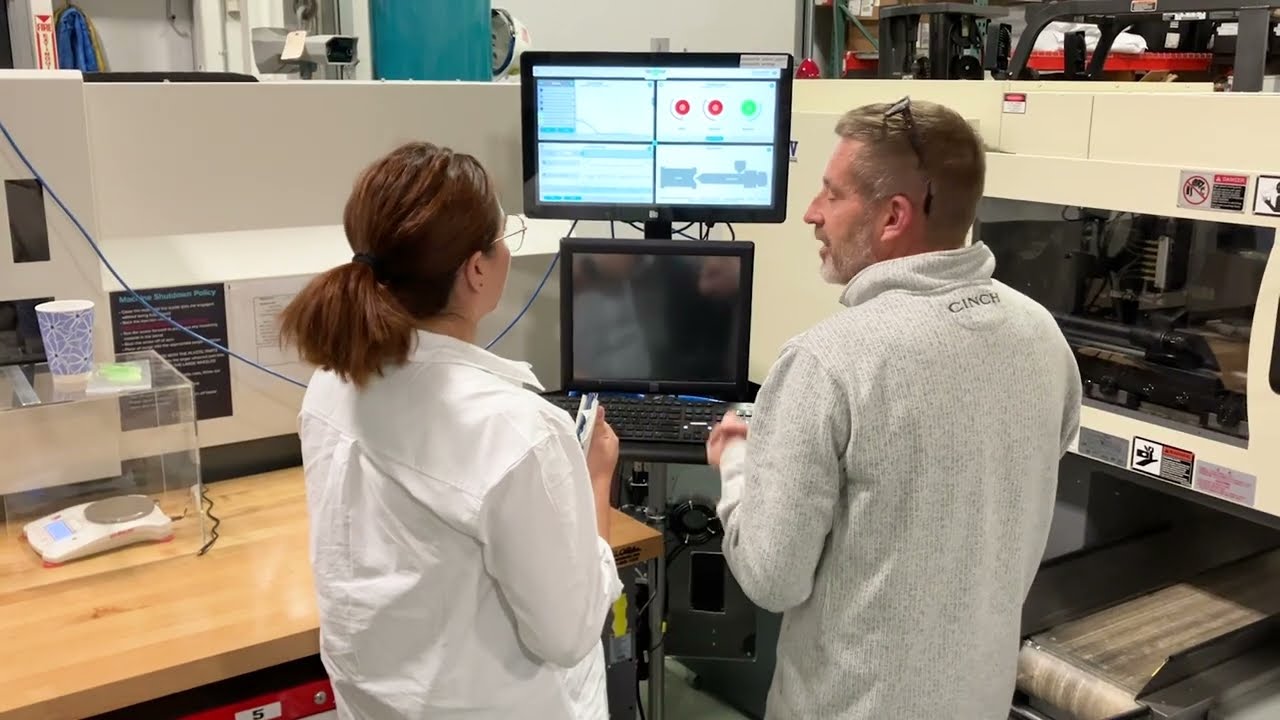

Upgrade to The CoPilot and take your injection molding to the next level. While eDART has been a trusted solution for decades, CoPilot is the next generation of evolving smart technology designed to help you stay competitive in an increasingly automated, data-driven industry.

This intuitive, user-friendly process control system ensures you deliver only the highest quality parts—every time. With advanced automation, real-time insights, and built-in process optimization, it minimizes waste, boosts efficiency, and helps bridge the skills gap in your workforce.

The future of injection molding is here. Don’t get left behind. Trade in your eDART systems today and get up to $6,000 each toward your CoPilot upgrade!

Ready to upgrade your injection molding operations?

Discover your eDART trade-in value & request a free demo: